Domestic USB Type-C manufacturers in 2024: opportunities and challenges

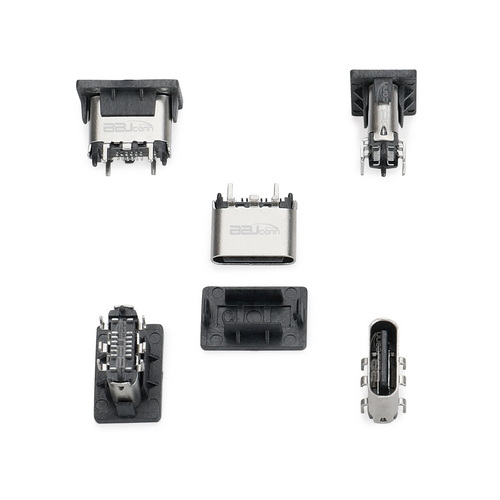

发布时间:2024-03-31作者:Shenzhen BBJ technology co., LTD点击:886

Domestic USB Type-C manufacturers in 2024: opportunities and challenges

As a new connection standard, the USB Type-C interface has been widely used in various electronic devices. In 2024, domestic USB Type-C manufacturers will face many opportunities and challenges, which require comprehensive analysis and response to ensure they remain competitive and continue to grow in the fiercely competitive market.

USB TYPE-C manufacturers will usher in many opportunities in 2024. First of all, with the rapid development of 5G networks and the popularity of smart devices, the demand for USB Type-C interfaces will further increase. Domestic manufacturers can meet market demand and achieve more sales growth by providing high-quality, high-performance USB Type-C products. Secondly, with the rise of emerging markets such as smart homes and smart wearable devices, the USB Type-C interface will be adopted by more different types of devices, providing opportunities for manufacturers to expand new market space.

However, USB TYPE-C manufacturers will also face some challenges. First of all, market competition is becoming increasingly fierce. Domestic and foreign manufacturers are increasing their investment in research and development of USB Type-C technology and products, and the phenomenon of product homogeneity in the market is serious. Therefore, manufacturers need to continuously improve their technical strength and product quality to stand out in the fierce market competition. Secondly, the uncertainty of the international trade environment has also brought certain challenges to USB Type-C manufacturers, which may affect the stability of the supply chain and product exports. Manufacturers need to strengthen risk management and response capabilities to reduce uncertainty. The impact of certainty.

Another opportunity facing USB TYPE-C manufacturers in 2024 is technological innovation and industrial upgrading. With the continuous advancement of technology, the technology of USB Type-C interface is also constantly evolving, such as supporting higher power fast charging, faster data transmission speed, etc. Domestic manufacturers can seize this opportunity, increase technology research and development efforts, and launch more competitive products to seize the opportunity in the market. At the same time, industrial upgrading will also bring new development opportunities to USB Type-C manufacturers, such as the integration and optimization of the industrial chain, the application of intelligent manufacturing technology, etc. Manufacturers can jointly promote the development of the industry and achieve development on a larger scale.

However, USB TYPE-C manufacturers also need to deal with some challenges. First of all, the long-term layout of the industrial chain and the stability of the supply chain are important issues that manufacturers need to pay attention to. Especially in the current situation where the global supply chain is affected by many uncertain factors, manufacturers need to strengthen the management and control of the supply chain to ensure that the supply of raw materials and product production are not affected. Secondly, intellectual property protection and market supervision are also issues that manufacturers need to pay attention to. As market competition intensifies, problems such as intellectual property infringement may increase. Manufacturers need to strengthen the protection of intellectual property rights, improve market supervision capabilities, and safeguard their legitimate rights and interests and market order.

To sum up, domestic USB Type-C manufacturers will not only face many opportunities in 2024, such as market demand growth, technological innovation and industrial upgrading, but also face some challenges, such as fierce market competition, supply chain management and intellectual property protection. wait. Only by fully understanding and grasping these opportunities and challenges, and continuously improving our competitiveness and response capabilities, can we remain invincible in the fiercely competitive market and achieve sustained and steady development.