Application Trends of Board-to-Board Connectors in 5G Communication Equipment

发布时间:2025-07-03作者:Shenzhen BBJ technology co., LTD点击:285

Application Trends of Board-to-Board Connectors in 5G Communication Equipment

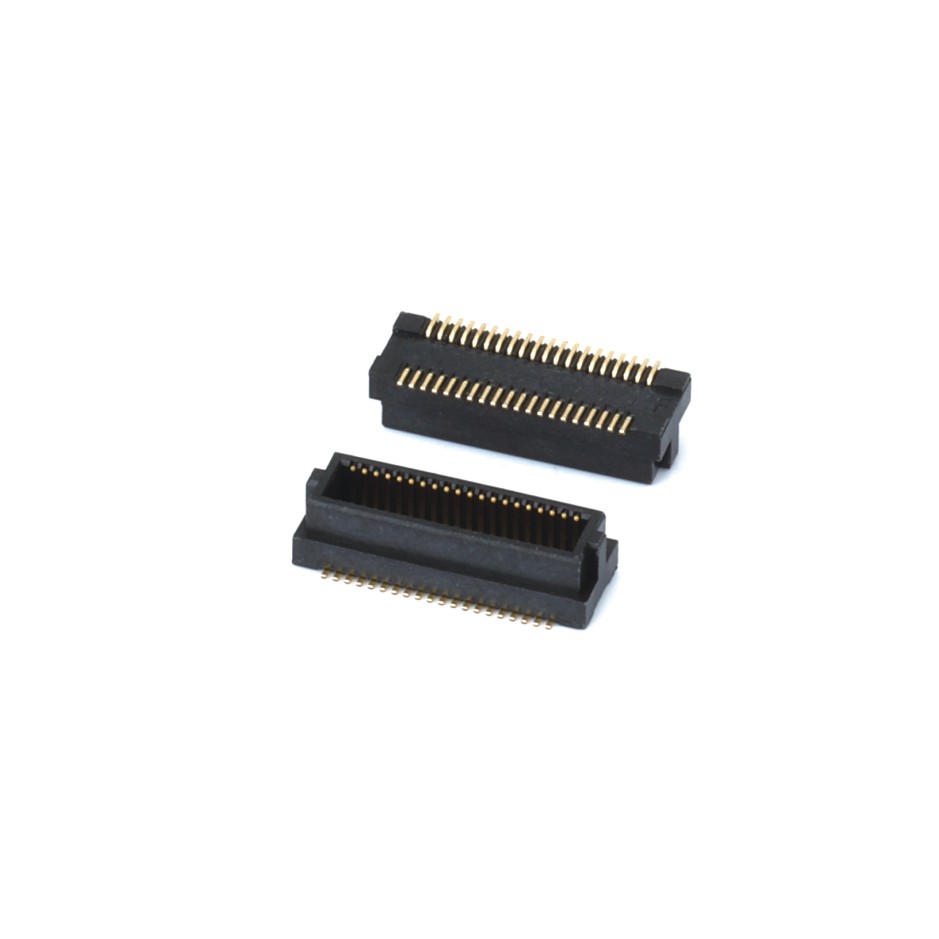

As a core component for high-speed signal and power transmission between motherboards, sub-boards and modules in electronic systems, board-to-board connectors are playing an increasingly critical role in 5G communication equipment. With the rapid deployment of 5G networks and the strong demand for high-frequency and high-speed connections in base stations, miniaturized equipment, and big data processing terminals, the technical development and application trends of board-to-board connectors are accelerating.

The primary advantage of board-to-board connectors in 5G communication equipment is its high-density and high-bandwidth transmission capability. The data transmission rate of 5G systems has increased by more than 10 times compared to 4G, and faster and more stable data exchange is required inside core devices. In order to cope with application scenarios such as multi-channel MIMO and large-scale antenna arrays, board-to-board connectors usually need to support multi-channel high-speed differential signals (such as 28Gbps, 56Gbps or even 112Gbps or more), while maintaining extremely low insertion loss and crosstalk performance to ensure data integrity between 5G communication modules.

The application of board-to-board connectors in 5G base station equipment is particularly typical. In macro base stations and small base station equipment, multiple sets of board-to-board connectors are often used for parallel transmission between the RF front-end module (RRU) and the main board, and between the RF module and the power control module. These connectors need to have good anti-interference and shielding capabilities to adapt to complex electromagnetic environments, and ensure connection reliability by optimizing the PIN pin structure, increasing the grounding design, and using EMI shielding materials.

On the 5G terminal side, such as CPE, industrial routers, and edge computing nodes, the equipment is becoming thinner and more compact, which puts higher requirements on the miniaturization and high reliability of board-to-board connectors. At present, mainstream products are developing towards precision board-to-board connectors with a pitch of 0.4mm, 0.35mm, and even 0.25mm to minimize space occupation, while taking into account the characteristics of high temperature resistance, vibration resistance, and plug-in resistance to ensure long-term use without looseness and cold soldering.

The application of board-to-board connectors in 5G communication equipment also faces the challenge of high-speed signal integrity design. For example, between the processor and high-speed storage and AI computing modules, the board-to-board connector plays a key role as a data bridge. Manufacturers need to optimize transmission paths and reduce signal reflection and loss through precise impedance control, low-capacitance materials, and three-dimensional simulation design to adapt to high-speed interface protocols such as PCIe Gen4, Gen5, and SerDes.

From the application trend, the future board-to-board connectors in the 5G communication field will present the following directions:

Simultaneous advancement of high-speed and low-loss design: Connectors need to support higher frequencies, lower reflections, and crosstalk performance to cope with high-throughput scenarios such as AI, big data, and edge computing.

Miniaturization and high-current design: Achieve a connection solution with smaller volume, higher PIN number, and greater current carrying capacity without sacrificing electrical performance.

Reliability design upgrade: To cope with the high temperature, humidity, and vibration environment of outdoor deployment, connectors need to have higher weather resistance and life guarantee.

Automation assembly-friendly design: To improve the mass production efficiency of 5G equipment, the connector structure needs to support industrial automation requirements such as automatic docking, blind plug structure, and reliable positioning.

Multi-protocol compatibility: The integration of communication equipment will continue to rise in the future, and connectors need to support composite connections of multiple high-speed interface protocols to improve design flexibility.

In summary, the application of board-to-board connectors in 5G communication equipment is no longer a simple connection function, but a core component that carries high-speed, stable, and scalable data transmission. As 5G networks move further towards the Internet of Everything, board-to-board connectors will also continue to upgrade at the technical level to promote efficient collaboration of the entire communication ecosystem.